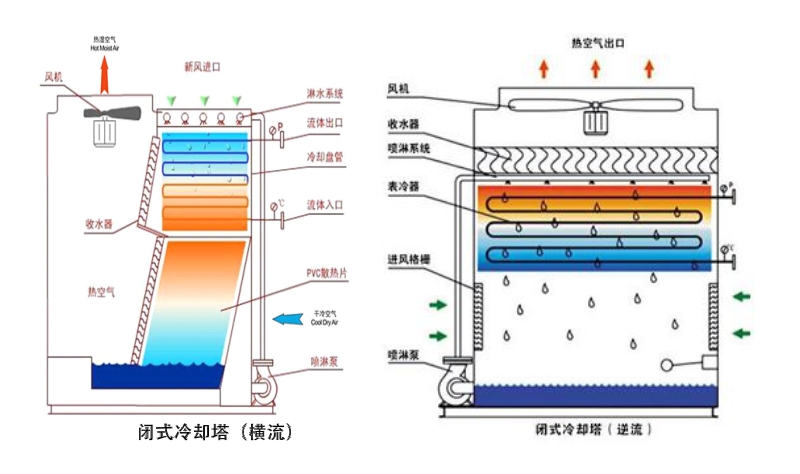

The principle of operation of the cooling tower

The tower is composed of a casing, heat exchanger(copper coil), fan, spray system, water collector, water tank and other parts.

When it works, the circular cooling medium (water, oil or other liquid) be driven by the main circulating pump between the heat exchanger and cooling equipment (such as: power, furnace body) .Water evenly sprayed on the heat exchanger become moisture film, while, air entering tower through the louver bar converses the spray water flow through the surface of heat exchanger. At the same time, heat exchanged is finished mostly between air and water by heat conduction and evaporation. Then, air become saturated is discharged to sky by fan. Water cooled that drop to the basin is transported to the sprinkler system. And so forth, medium in heat exchanger becomes cooled.

Application condition

When the counter-flow closed tower runs, liquid of coil inside don’t touch with air outsides, to avoid congestion, terminal equipment contaminated due to fouling and corrosion problems, of course, to reduce the current maintenance trouble. It is satisfied in somewhere , the air dust polluted seriously,Poor water quality of the region, fluid process system uncontaminated, and so on. Be careful of water quality outside of coil, that is a way to keep the heat exchanging efficiency of the cooling tower.

In winter, special attention should be paid to the problem of freezing pipe. There is a simple method to add antifreeze into the system, other, must stop run to drain the liquid in the coil.

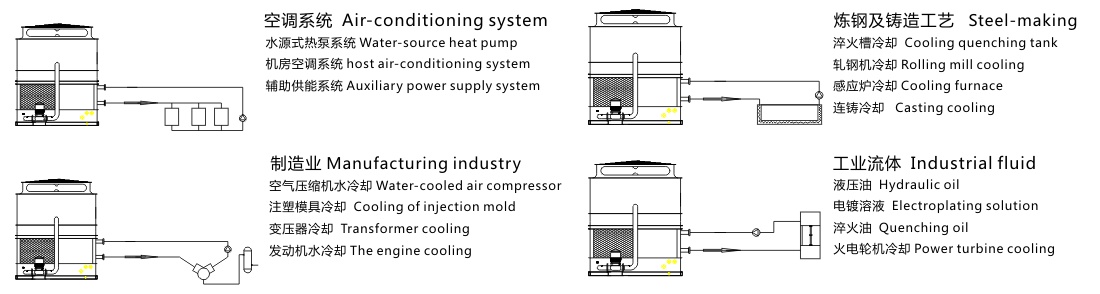

Applications are as follows :

Case

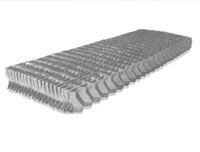

Case of tower is make from Z.A.M that have superior resistance to corrosion, corrosion and rust proof function 15 times than common steel, Surface bright, high hardness, excellent resistance, environmental protection, beautiful.

Other parts is make from high grade H.D.G.S.

Motor

The built-in structure design of the r motor is totally enclosedspecial for cooling tower, Ip55, F class, applicable to 380V/3/50HZ power supply. We can also provide motor using other power supply according to user requirements or equipped with double speed or frequency conversion motor.

Fan

Streamline airfoil fan, make from A.C, low speed operation, low energy consumption, low noise, long service life.

The windmill angle can be adjusted freely according to the operating load.

Patent louver bar

Patent three one protection louver bar, be installed around the tower to protect water in basin from sunshine and algae.It is useful to duce requirement of water treatment and maintain cost daily .

Patent coil

It is a high pressure seamless deoxidized copper or S304 manuf-acturing, designspecial solid snake type structure, patent, has the optimal heat transfer effect and corrosion resistance.

Low pressure distributer

It is a special nozzle with low pressure, uniform spraying and not clog, weather resistance, corrosion resistance and other characteristics

Inside reducer system

It is standard products with quick assembling belt reducer, adopts imported waterproof anti-skid belt and imported high precision bearings, with long service life, low noise operation.

Well, we can apply gear reducer to user.

High efficiency collector

It is design of the corrosion of PVC material by the mold,packet installed inside of the tower , easy disassembly. It can remove exhaust airflow in the residual water, cooling tower outlet water drift rate of less than 0.001%.